Sab hauv cov hlua hluav taws xob ntawm lub hwj chim faib txee Internal txuas xov hlau ntawm lub hwj chim faib tswj lub thawv nrog txuas cov xov hlau ntawm lub hauv paus chaw nres tsheb fais fab faib txee Sheng Hexin

Qhia peb cov khoom tshiab

Qhia peb cov khoom lag luam saum toj kawg nkaus, tsim kom tau raws li tag nrho koj cov kev xav tau kev sib txuas hluav taws xob. Peb cov xov hlau boasts ib tug dav array ntawm nta thiab ntawv pov thawj uas ua rau nws ib tug txhim khu kev qha thiab zoo xaiv rau ntau yam kev siv.

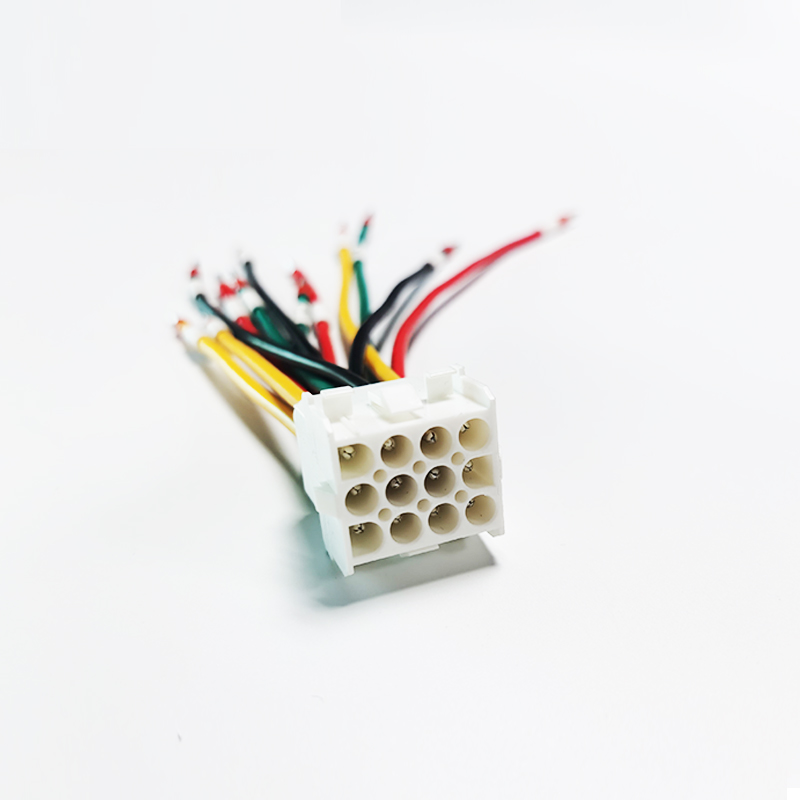

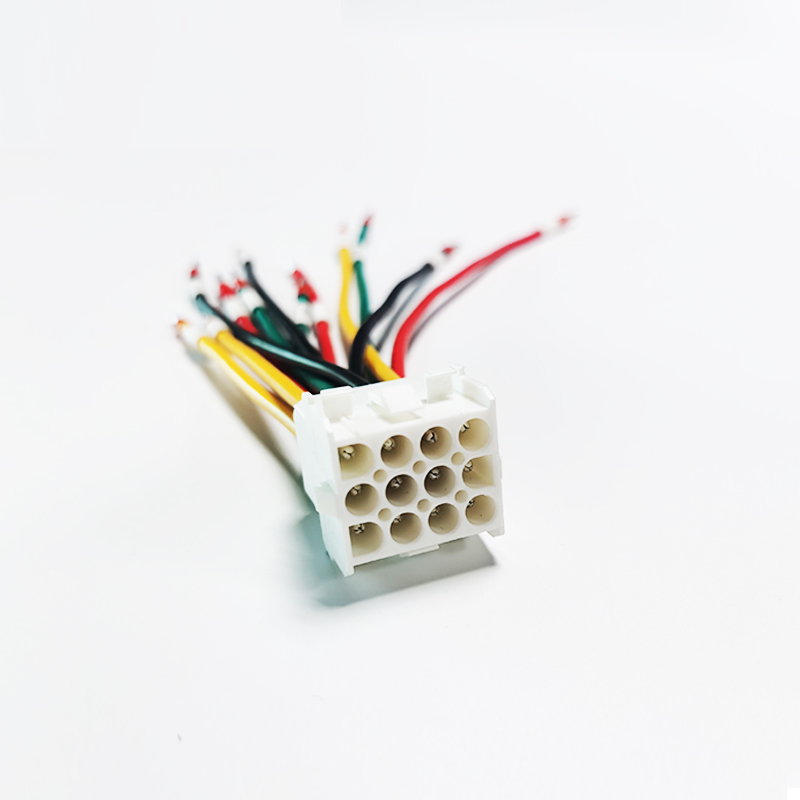

Ib qho tseem ceeb feature ntawm peb cov hlau yog nws cov customizable loj xaiv. Peb nkag siab tias cov haujlwm sib txawv yuav tsum muaj qhov sib txawv ntawm qhov sib txawv, thiab peb cov khoom tso cai rau koj xaiv qhov loj me uas haum rau koj cov kev xav tau. Qhov no ua kom ntseeg tau tias cov hlau uas koj xaiv yuav zoo kawg nkaus phim koj qhov project specifications.

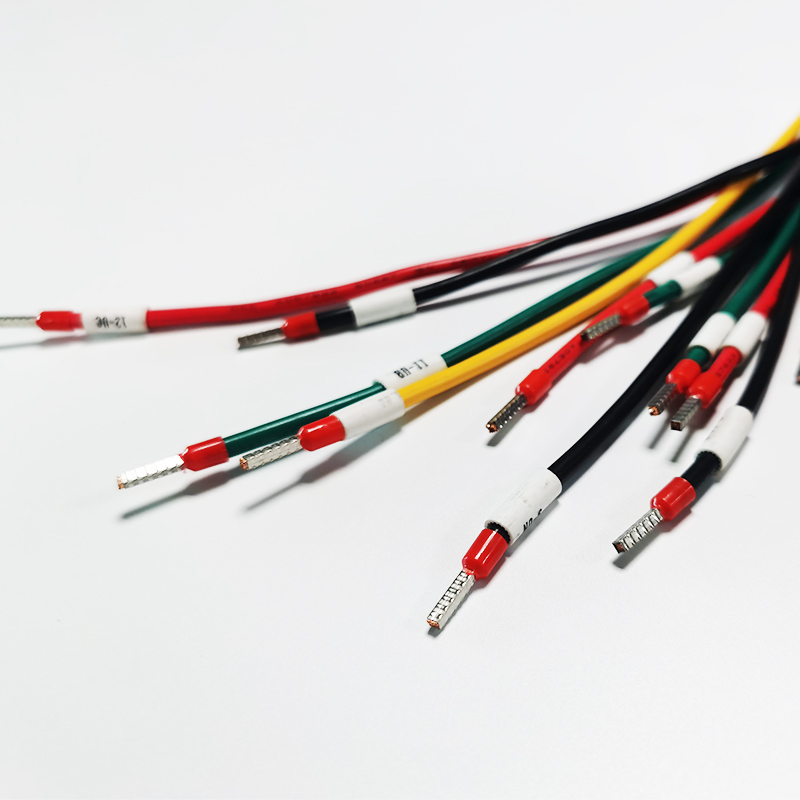

Tsis tas li ntawd, peb cov hlau yog tsim los nrog cov kev faib ua haujlwm kom meej thiab muaj cov lej cim kom meej. Qhov no ua rau nws yooj yim los txheeb xyuas thiab teeb tsa cov kev sib txuas, txhim kho kev yooj yim thiab kev ua haujlwm zoo thaum lub sijhawm teeb tsa thiab kho cov haujlwm.

Product Description

Lub hau sab nraud ntawm peb cov hlau yog tsim los ntawm cov roj hmab muaj zog PVC. Cov khoom no muab lub zog tshwj xeeb, tiv thaiv kev qaug zog, thiab ruaj khov hauv qhov loj. Nws kuj muaj qhov ua tau zoo heev rau kev laus thaum tshav kub kub, folding, thiab dabtsi yog khoov, ua rau nws tsim nyog siv rau ntau qhov chaw. Nrog rau qhov kub ntawm -40 ℃ to 105 ℃, peb cov hlau tuaj yeem siv tau txhua xyoo, txawm tias huab cua huab cua tsis zoo.

Txhawm rau lav qhov kev ntseeg siab tshaj plaws, peb cov khoom sib txuas thiab cov khoom sib txuas yog tsim los siv tooj dag stamping thiab kev tsim cov txheej txheem. Qhov no tsis tsuas yog txhim kho hluav taws xob conductivity tab sis kuj ua kom ruaj khov thiab txhim khu kev qha ntawm cov khoom siv hluav taws xob. Tsis tas li ntawd, qhov saum npoo yog tin-plated los tiv thaiv oxidation, ncua lub neej ntawm cov connectors thiab tiv thaiv corrosion.

Peb cov hlau yog ua raws li UL thiab VDE ntawv pov thawj, nrog rau REACH thiab ROHS2.0 cov qauv. Qhov no qhia tau hais tias peb txoj kev cog lus los tsim cov khoom muaj kev nyab xeeb thiab ib puag ncig zoo. Rau cov neeg siv khoom uas xav tau cov ntaub ntawv ntawm kev ua raws cai, peb tuaj yeem muab REACH thiab ROHS2.0 cov ntawv ceeb toom thaum thov.

Ntawm peb lub tuam txhab, peb nkag siab tias txhua qhov project yog qhov tshwj xeeb. Tias yog vim li cas peb muab cov kev xaiv customization rau ntau lawm. Txawm hais tias koj xav tau qhov ntev, xim, lossis cov yam ntxwv ntxiv, peb tuaj yeem ua raws li koj qhov yuav tsum tau ua. Peb pab neeg ntawm cov kws tshaj lij yuav ua haujlwm nrog koj los xyuas kom meej tias cov khoom kawg ua tau raws li koj cov lus qhia meej.

Nrog peb cov xaim, koj tuaj yeem tau txais txiaj ntsig zoo tias txhua qhov kev nthuav dav tau raug tsim los ua kom tau raws li cov qauv siab tshaj plaws. Peb qhov kev cog lus rau kev ua tau zoo yog qhov tsis hloov pauv, thiab peb lub hom phiaj ntawm kev muab cov khoom lag luam txhim khu kev qha thiab muaj txiaj ntsig yog qhov ua rau peb sib nrug ntawm kev sib tw. Xaiv peb cov xov hlau rau koj qhov project tom ntej, thiab paub qhov txawv ntawm cov khoom siv tes ua haujlwm zoo tshaj plaws thiab kev saib xyuas kom meej.